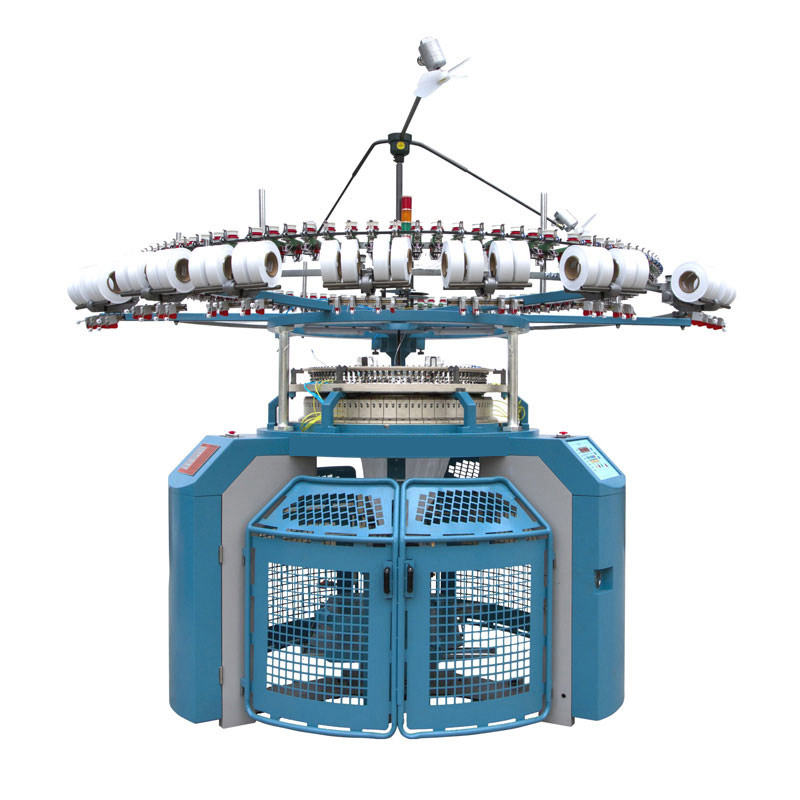

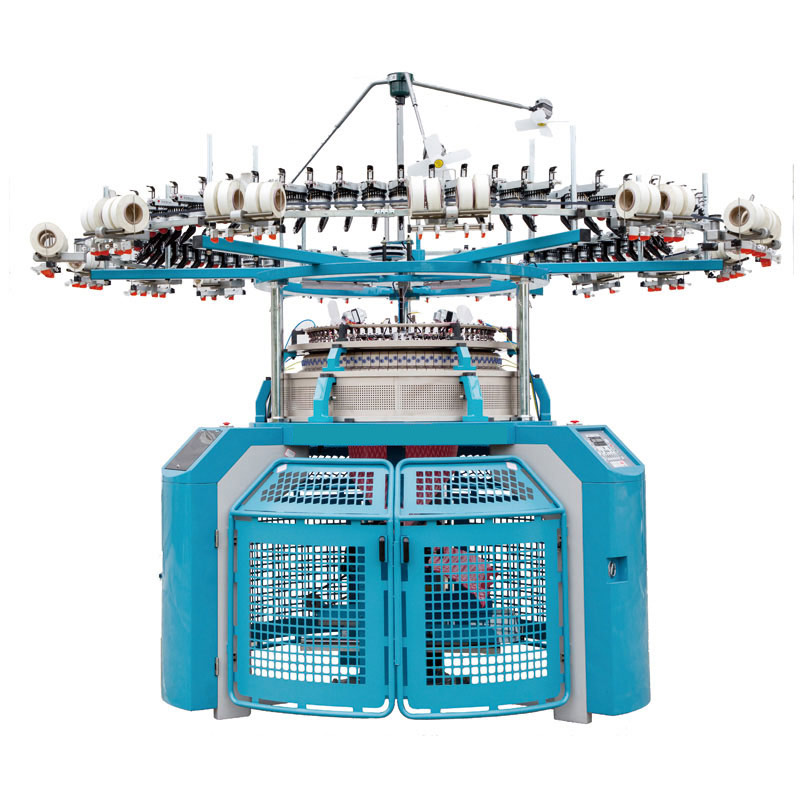

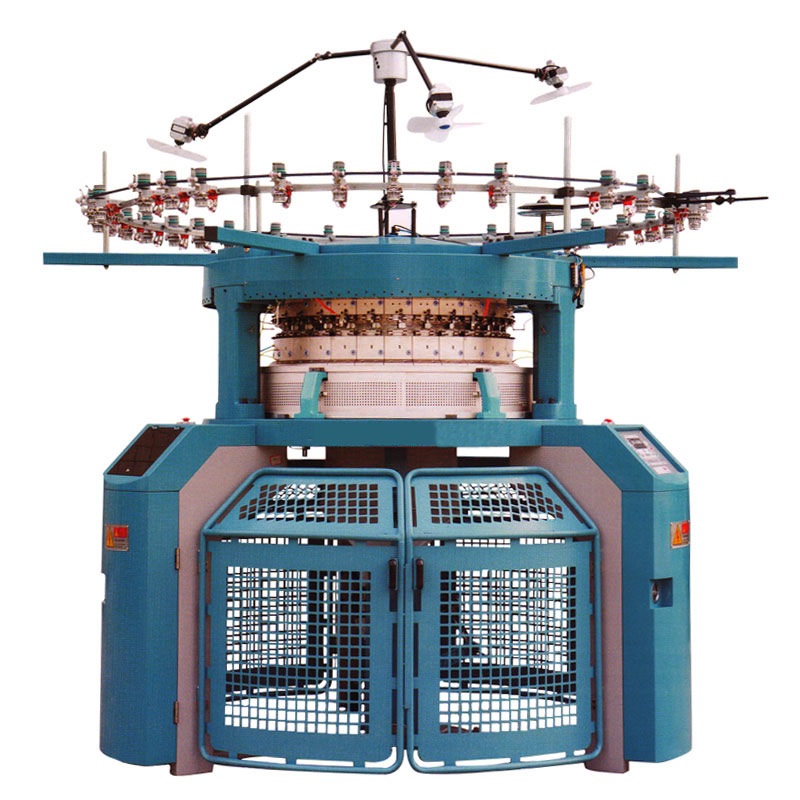

Feature:

The frame of the machine combines the knitting principal with human engineering, which makes the machine firm and pretty. High quality cast iron is employed for natural aging process, which prevents parts from deforming and provides better quality.

By changing the core parts only, single knitting machines can be transformed into terry machines or fleece machines, which help improve efficiency and brings about flexibility in knitting.

All cams made of imported alloy steel are carved and ground in the CNC machine, which makes the needle track smooth and the needle durable while machines run at high speed. The streamlined cams are easy to adjust which also makes the needle smooth and stable at high speed.

With a compact structure, the newly designed central stitch system works smoothly and steadily and adjusts fabric weight simply and accurately, which help improve efficiency.

Unique drive system with specially designed dual tracks reduces wear and makes the machine run more smoothly with less barre marks.

Main technical data:

| Specifications FS Series – Single Jersey Knitting Machine | |

|---|---|

| MODEL | FS Series – Single Jersey Knitting Machine |

| CYLINDER DIAMETER | 12″~52″ |

| GAUGE | 12G ~ 43G |

| FEEDER NUMBER | 36F ~ 312F |

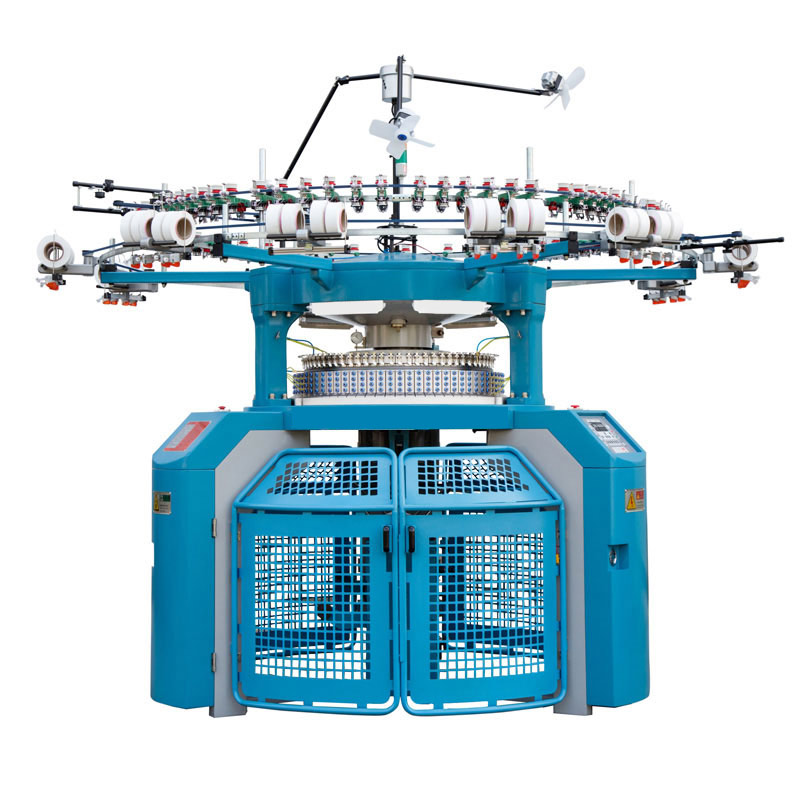

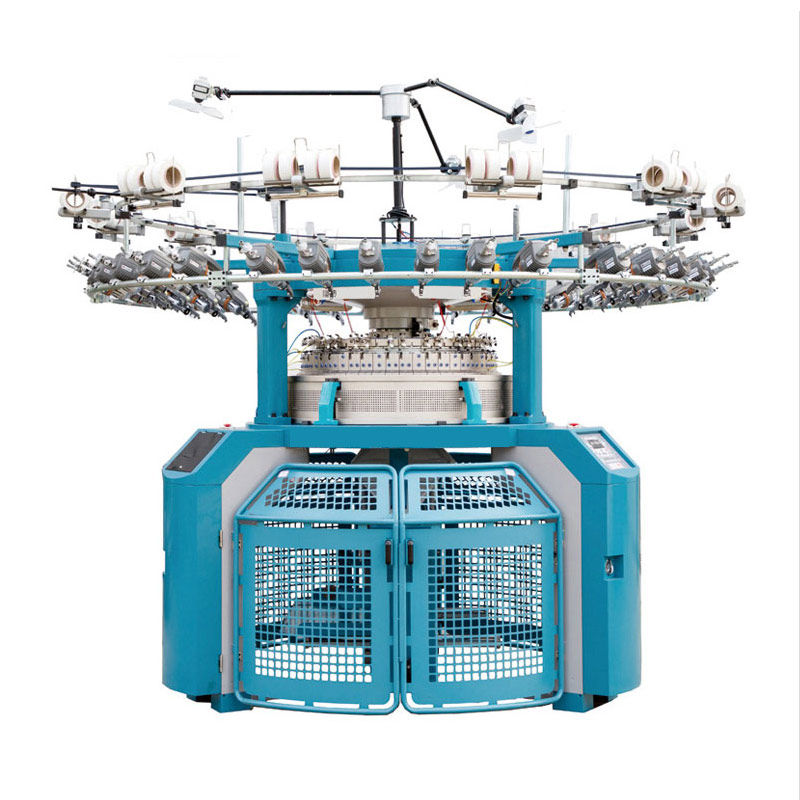

Feature:

Top and bottom gears are designed to be immersed in lubricants in order to abate the noise, reduce wear, improve accuracy and enhance durability.

Employing newly designed machine frame, the dial cam box base and the bush sleeve move synchronously, which makes the adjustment of needle deviation and space simply and accurately.

Multi functional machines, equipped with 2-track cams in the dial and 4-track cams in the cylinder, can produce different double jersey fabric by changing the order of the cams.

Dual dedusting system of cylinder: The upper needle dial and lower cylinder of the machine are designed to be equipped with dedusting fans which clean cotton dust more effectively, which avoids the needle breakage and improves the quality of cloth.

Unique drive system with specially designed dual track reduces wear and makes the machine run more smoothly with less barre marks.

| Specifications FD Series – Double Jersey Knitting Machine | |

|---|---|

| MODEL | FD Series – Double Jersey Knitting Machine |

| CYLINDER DIAMETER | 14″ ~ 44″ |

| GAUGE | 12G ~ 44G |

| FEEDER NUMBER | 28F ~ 124F |

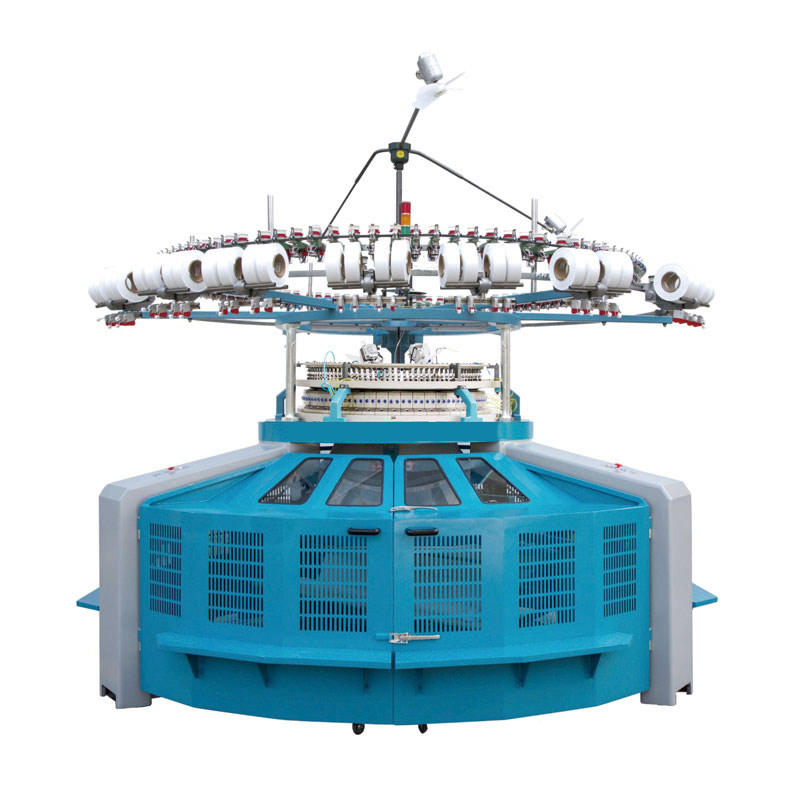

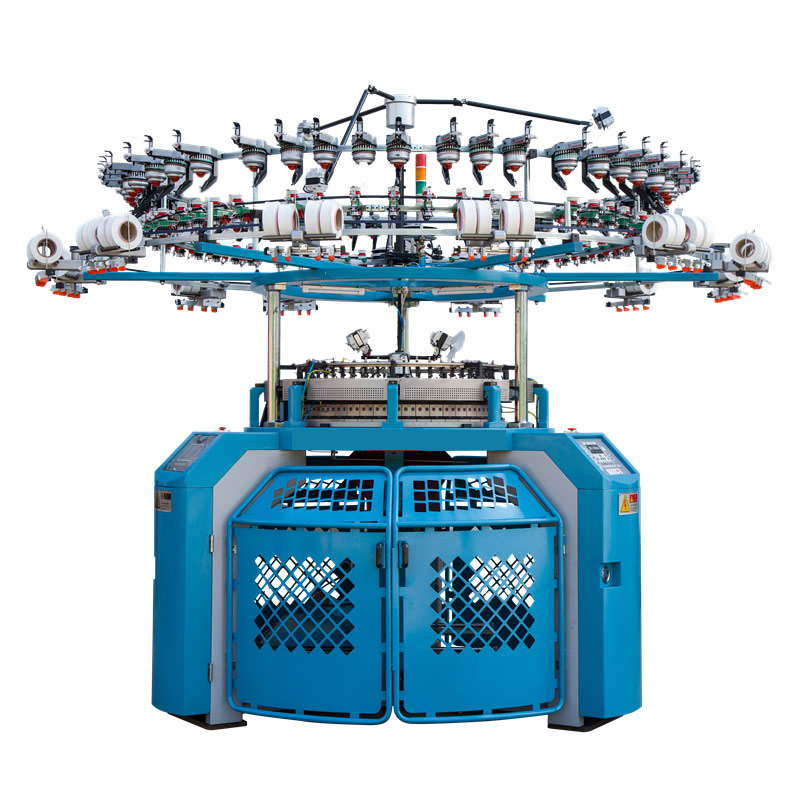

Feature:

Parts and accessories are manufactured by advanced machining center so that the precision and accuracy can be greatly improved.

The heart knitting system: The material of the cam is made through a special imported heat treatment process. The accessories of the heart adopt the precise positioning by CAD/CAM to ensure that the needle track is smooth enough to adopt various material and textile technologies.

Open-width system: The machine adopts the latest winder system and is equipped with the roller shifting device to ensure the uniform stitch density of fabric. The operation is easy and convenient, which makes full use of cloth by effectively removing creases in cloth caused by common winders.

With a compact structure, the newly designed central stitch system works smoothly and steadily and adjusts fabric weight simply and accurately, which help improve efficiency.

Unique drive system with specially designed dual tracks reduces wear and makes the machine run more smoothly with less barre marks.

| Specifications FSO Series – Single Jersey Open-width Knitting Machine | |

|---|---|

| MODEL | FSO Series – Single Jersey Open-width Knitting Machine |

| CYLINDER DIAMETER | 26″ ~ 44″ |

| GAUGE | 14G ~ 44G |

| FEEDER NUMBER | 78F ~ 132F |

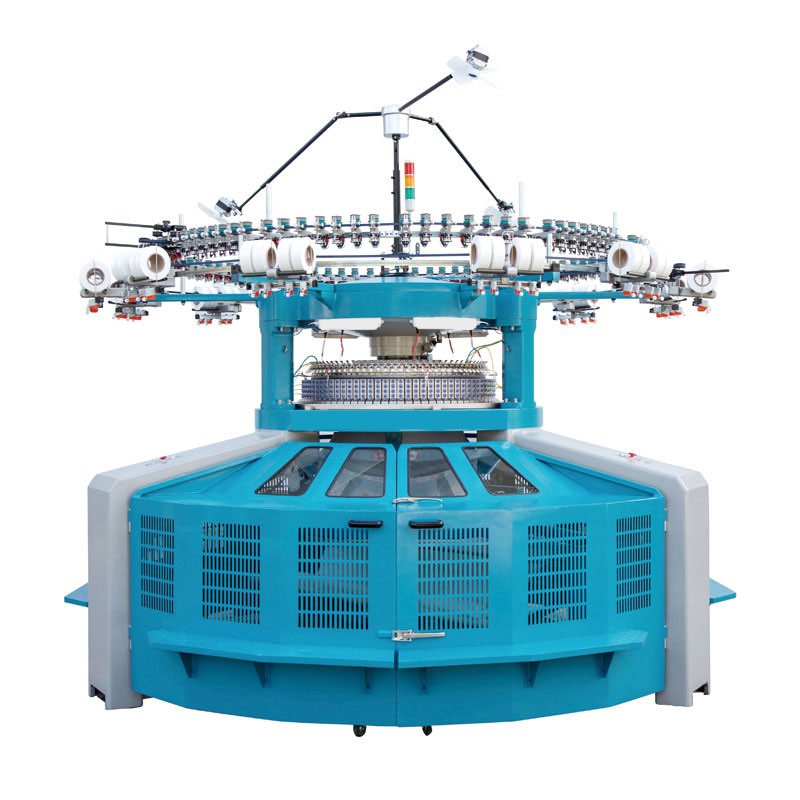

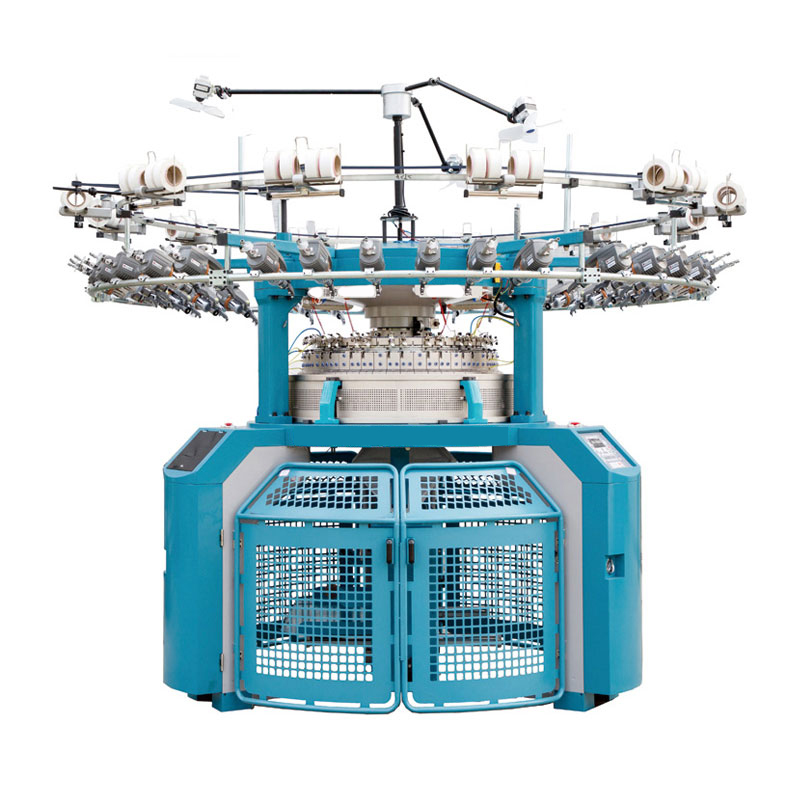

Feature:

The Small Diameter Double Jersey Knitting Machine is the reinforced mini version based on Double Jersey Knitting Machine.

Immersed in lubricants, top and bottom gears are more durable, and they are more synchronous than general circular knitting machines.

Each cam is adjustable independently to make a variety of fabric. It share the same function on knitting with Lycra or covered yarn.

The machine can run at 80~110 rpm very stably..

This all new mini version of the circular knitting machine is durable and stable enough to make beautiful and smooth fabrics.

| Specification FDO Series – Small Diameter Double Jersey Knitting Machine | |

|---|---|

| MODEL | FDO Series – Small Diameter Double Jersey Knitting Machine |

| CYLINDER DIAMETER | 7″ ~ 13″ |

| GAUGE | 7G ~ 40G |

| FEEDER NUMBER | 14F ~ 26F |

Feature:

The machine, unlike common jacquard machines, uses computerized selectors to select needles in the cylinder with the 3-way technique of knit, tuck and miss, which can produce fabric with different patterns without limitation. This function is also time-saving on changing patterns. Any intricate pattern of fabric can be converted via computerized pattern preparation system into the special control command which instructs selectors to make jacquard fabric.

The control system is designed to install the electronic computer processing system and computerized selectors together in the machine with the most advanced micro-processing technology. The machine adopts touch LCD display screens to simply the operation, save space and keep itself clean and tidy.

No specific softwares and needed for graphics but common ones. Any cloth cover or pattern can be scanned into or programmed and input into computers, edited, converted into needle selecting programs by WAC Designer, put into USB and run on the machine.

| Specifications FSC Series – Computerized Single Jacquard Knitting Machine | |

|---|---|

| MODEL | FSC Series – Computerized Single Jacquard Knitting Machine |

| CYLINDER DIAMETER | 14″ ~ 44″ |

| GAUGE | 7G ~ 32G |

| FEEDER NUMBER | 34F ~ 84F |

Feature:

The machine uses computerized selectors to select needles in the cylinder with the 2-way or 3-way technique of knit, tuck and miss, which can produce fabric with different patterns without limitation. Any intricate pattern of fabric can be converted via computerized pattern preparation system into the special control command which instructs selectors to make jacquard fabric.

The control system is designed to install the electronic computer processing system and computerized selectors together in the machine with the most advanced micro-processing technology. The precise encoder can accurately calculate the needle position and zero-point calibration to ensure the stability of needle selection system. The machine adopts touch LCD display screens to simply the operation, save space and keep itself clean and tidy.

No specific software’s are needed for graphics but common ones. Any cloth cover or pattern can be scanned into or programs by WAC Designer, put into USB and run on the machine.

| Specifications FDC Series – Computerized Double Jacquard Knitting Machine | |

|---|---|

| MODEL | FDC Series – Computerized Double Jacquard Knitting Machine |

| CYLINDER DIAMETER | 18″ ~ 42″ |

| GAUGE | 7G ~ 32G |

| FEEDER NUMBER | 34F ~ 84F |

Feature:

Controlled by the computer, this series of machines can select needles and make jacquard fabrics with patterns from the USB, With pattern designing software easy to use, it also contains the three-way technique and the power-off memory function.

It is easy to test and operate the machine by taking user’s operating habits into consideration

The control system is designed to install the electronic computer processing system and computerized selectors together in the machine with the most advanced micro-processing technology. The machine adopts touch LCD display screens to simply the operation, save space and keep itself clean and tidy.

| Specifications Computerized Single Jersey Terry Jacquard Knitting Machine | |

|---|---|

| MODEL | Computerized Single Jersey Terry Jacquard Knitting Machine |

| CYLINDER DIAMETER | 14″ ~ 44″ |

| GAUGE | 7G ~ 32G |

| FEEDER NUMBER | 34F ~ 84F |

Feature:

This new type of knitting machine is elaborately developed by FuFang following the global trend of garment development. With computerized jacquard technology integrated with knitting weaving technology, the machine can produce exquisite fashion fabric with jacquard, loop transfer as well as 3D patterns.

The machine with 2-way computerized selecting technique to select needles, unlike common jacquard machines, can produce fabric with different patterns without limitation. This function is also time-saving on changing patterns.

The control system is designed to install the electronic computer processing system and computerized selectors together in the machine with the most advanced micro-processing technology. The precise encoder can accurately calculate the needle position and zero-point calibration to ensure the stability of needle selection system. The machine adopts touch LCD display screens to simplify the operation, save space and keep itself clean and tidy.

No specific softwares are needed for graphics but common ones. Any fabric design or pattern can be scanned into or programmed and input into computers, edited, converted into needle selecting programs by WAC Designer, put into USB and run on the machine.

| Specifications Double Loop Transfer Rib Computerized Jacquard Knitting Machine | |

|---|---|

| MODEL | FDC Series – Double Loop Transfer Rib Computerized Jacquard Knitting Machine |

| CYLINDER DIAMETER | 17″ ~ 42″ |

| GAUGE | 7G ~ 20G |

| FEEDER NUMBER | 27F ~ 68F |

Feature:

The machine uses computerized selectors to select needles in the cylinder with the 2-way or 3-way technique of knit, tuck and miss, which can produce fabric with different patterns without limitation. Any intricate pattern of fabric can be converted via computerized pattern preparation system into the special control command which instructs selectors to make jacquard fabric.

The control system is designed to install the electronic computer processing system and computerized selectors together in the machine with the most advance micro-processing technology. The precise encoder can accurately calculate the needle position and zero-point calibration to ensure the stability of needle selection system. The machine adopts touch LCD display screens to simplify the operation, save space and keep itself clean and tidy.

No specific softwares are needed for graphics but common ones. Any fabric design or pattern can be scanned into or programmed and input into computers, edited, converted into needle selecting programs by WAC Designer, put into USB and run on the machine.

| Specifications FDC Series – Linking Computerized Jacquard Knitting Machine | |

|---|---|

| MODEL | FDC Series – Linking Computerized Jacquard Knitting Machine |

| CYLINDER DIAMETER | 30″ ~ 38″ |

| GAUGE | 7G ~ 19G |

| FEEDER NUMBER | 18F ~ 32F |

3V International is a global group who have been supplying Textile Machinery products around the world since 1999.

© 2021 3V International. All rights reserved.